咨询热线

产品介绍

- 设备图片:

性能特点

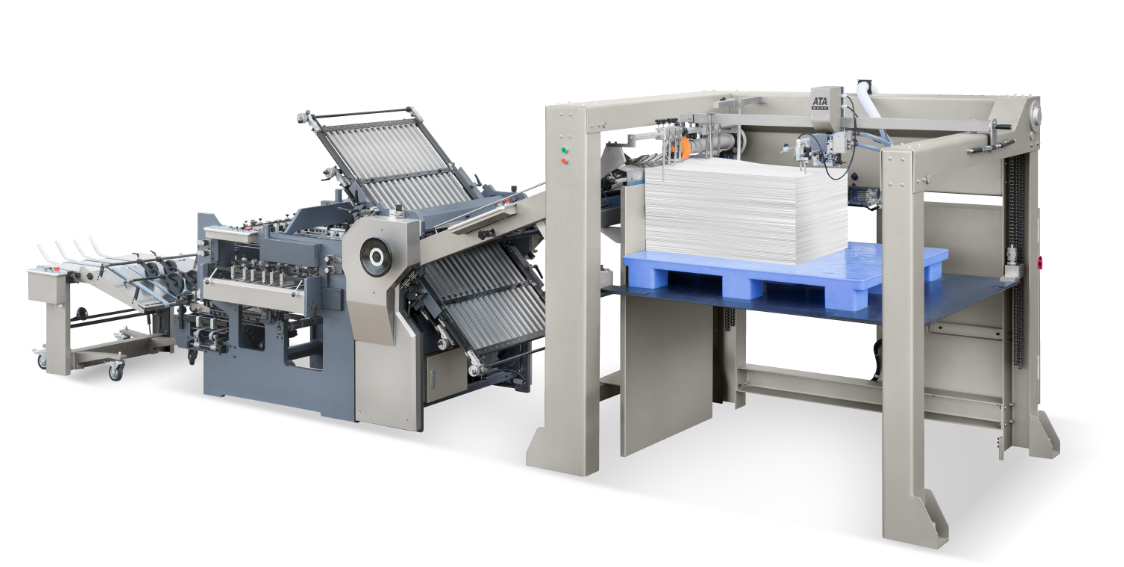

1 ZYHD780C-LD为龙门架上纸系统的混合式电控刀折页机, 可进行四次平行折页和三次垂直折页,按需要配置24开双联装置。其中第三刀为反折

2 配有高精度纸位探测系统

3 采用高精度带十字联轴器的斜齿轮传动,同步性好、噪声低

4 直纹、钢质软聚氨脂的原装进口折辊,送纸力强,能减轻对印刷品的压痕。

5 整个电气控制系统采用微电脑控制,支持与计算机互联通信,各种控制参数通过人机界面设定

6 整机采用变频调速并具有变频过载保护功能

7 拥有灵敏的双张、堵塞自动控制功能

8 采用流线形按钮站,进口薄膜按键,操作方便,美观大方,经久耐用

9 具有故障点显示功能

10 可按需进行压痕、打孔和分切

11 每折独立的带伺服驱动的电控刀装置,高速、可靠、纸张损耗小。

ZYHD780 C机型,独立传动的反四折可通过前车按钮站转换开停。在三折页时可关停四折动力部分,减少零部件磨损,降低机器能源消耗

12 输纸方式采用纸台整车直接推进后走纸,可减少上纸停机时间,提高工作效率,减轻操作人员工作强度

13 配置加压堆积式收纸机,减轻劳动强度,提高工作效率(选配)

- Four buckle plates and three mechanically-controlled knives can carry out parallel folds and cross folds(the third knife performs reversed folding), optional twofold of 24-mo.

- High precise pile height detector.

- High precision helical gear guarantees perfect synchronization and low noise.

- The imported straight-grain steel folding rollers guarantee the best feeding force and reduce the indentation of paper.

- Electrical system is controlled by microcomputer , Modbus protocol realizes machine communicate with computer; Man-machine interface facilitates parameter input.

- Smoothly controlled by VVVF with overload protecting function.

- Sensitive automatic control device of double sheet and jammed sheet.

- Streamline buttons panel with import film key-press guarantees aesthetic surface and reliable operation;

- Malfunction display function facilitates troubleshooting;

- Scoring, perforating, and slitting at request;

Electrically controlled knife with servomechanism for each folding realizes high speed, superior reliability, and minor paper wastage.

- The forth folding can be switched on and off by the main button independently. While carrying out the third folding, the power part of forth folding can be stopped to reduce parts wear and cut the energy consumption down.

- Filling a full paper-table to feed, save time while braking the machine for feeding, improve the working efficiency and reduce the working intensity.

- Optional press delivery device or press device can reduce work intensity and improve work efficiency.

ZYHD780C-LD主要技术参数 Technical data:

|

机器型号 尺寸 |

Model |

ZYHD780C-LD |

|

可折最大纸张尺寸 |

Max. sheet size |

780×1160mm |

|

可折最小纸张尺寸 |

Min. sheet size |

150×200mm |

|

最高折页速度 |

Max. folding speed |

220m/min |

|

平行折最小折页宽度 |

Min. sheet width of parallel folding |

55mm |

|

折刀最高频率 |

Max. folding knife cycle rate |

350stroke/min |

|

可折纸张定量范围 |

Sheet range |

40-200g/m2 |

|

装机容量 |

Machine power |

8.74kw |

|

机器外形尺寸(长*宽*高) |

Overall dimensions(L×W×H) |

7000×1900×1800mm

|

|

机器重量 |

Machine net weight |

3000kg |

性能特点

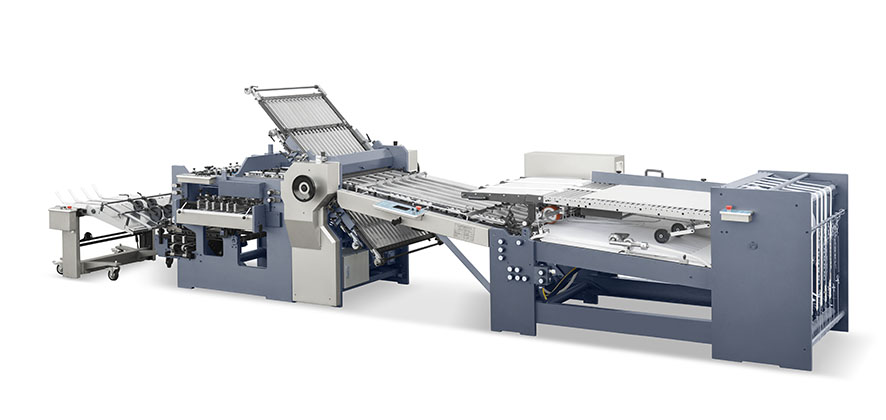

1 ZYHD780C-4JZZ-RD系环抱式电控刀折页机,可进行四次平行折页和三次垂直折页(第三刀为反折)。采用栅栏折页时,可进行四次平行折页,折页方式为平行式、卷筒式;垂直折页时第二、三、四折组分别由单独伺服电机控制折刀,来完成三次垂直折页。

2采用原装进口的直纹钢质折辊,送纸力强,能减轻对印刷品的压痕

3 整个电气控制系统采用微电脑控制,支持与计算机互联通信,各种控制参数通过人机界面设定

4 整机采用变频调速并具有变频过载保护功能, 配有高精度纸位探测系统

拥有灵敏的双张、堵塞自动控制功能,具有故障点显示功能,可按需进行压痕、打孔和分切

5 独立传动的反四折可通过前车按钮站转换开停。在三折页时可关停四折动力部分,减少零部件磨损,降低机器能源消耗

6每折独立的带伺服驱动的电控刀装置,高速、可靠、纸张损耗小

7 采用回转式给纸,上纸不停机,可提高机器工作效率达30%

- Four buckle plates and three mechanically-controlled knives can carry out parallel folds and cross folds(the third knife performs reversed folding). Buckles can perform four parallel folds, the folding ways are parallel and reel. Three cross folds are each completed by knife which is controlled by servo motor on the second, third and four folding unit.

- The imported straight-grain steel folding rollers guarantee the best feeding force and reduce the indentation of paper.

- Electrical system is controlled by microcomputer , Modbus protocol realizes machine communicate with computer; Man-machine interface facilitates parameter input.

- Smoothly controlled by VVVF with overload protecting function. High precise pile height detector. Sensitive automatic control device of double sheet and jammed sheet. Malfunction display function facilitates troubleshooting; Scoring, perforating, and slitting at request;

- The forth folding can be switched on and off by the main button independently. While carrying out the third folding, the power part of forth folding can be stopped to reduce parts wear and cut the energy consumption down.

- Electrically controlled knife with servomechanism for each folding realizes high speed, superior reliability, and minor paper wastage.

- Rotary sheet feeding realizes sheet feeding without braking machine, it improves the work 30% in efficiency.

ZYHD780C-RD主要技术参数Technical data:

|

尺寸 |

Model |

ZYHD780C-RD |

|

可折最大纸张尺寸 |

Max. sheet size |

780×1160mm |

|

可折最小纸张尺寸 |

Min. sheet size |

150×200mm |

|

最高折页速度 |

Max. folding speed |

220m/min |

|

平行折最小折页宽度 |

Min. sheet width of parallel folding |

55mm |

|

折刀最高频率 |

Max. folding knife cycle rate |

350stroke/min |

|

可折纸张定量范围 |

Sheet range |

40-200g/m2 |

|

装机容量 |

Machine power |

8.74kw |

|

Overall dimensions(L×W×H) |

7000×1620×1630mm |

|

|

机器重量 |

Machine net weight |

3000kg |

性能特点

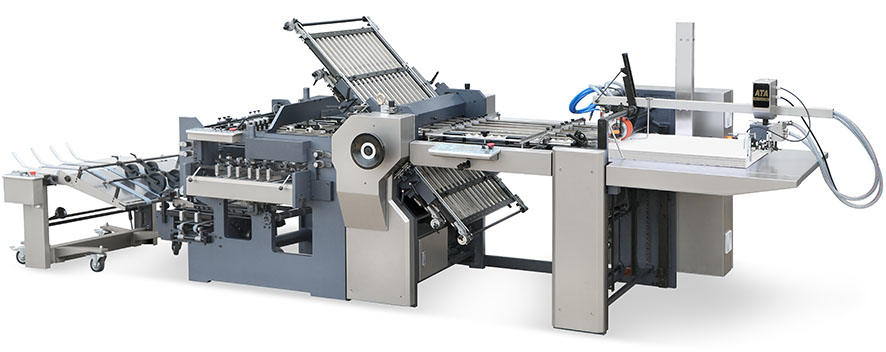

1 ZYHD780C-4JZZ系电控刀折页机,可进行四次平行折页和三次垂直折页(第三刀为反折)。采用栅栏折页时,可进行四次平行折页,折页方式为平行式、卷筒式;垂直折页时第二、三、四折组分别由单独伺服电机控制折刀,来完成三次垂直折页。

2采用原装进口的直纹钢质折辊,送纸力强,能减轻对印刷品的压痕

3 整个电气控制系统采用微电脑控制,支持与计算机互联通信,各种控制参数通过人机界面设定

4 整机采用变频调速并具有变频过载保护功能, 配有高精度纸位探测系统

拥有灵敏的双张、堵塞自动控制功能,具有故障点显示功能,可按需进行压痕、打孔和分切

5 独立传动的反四折可通过前车按钮站转换开停。在三折页时可关停四折动力部分,减少零部件磨损,降低机器能源消耗

6每折独立的带伺服驱动的电控刀装置,高速、可靠、纸张损耗小

- Four buckle plates and three mechanically-controlled knives can carry out parallel folds and cross folds(the third knife performs reversed folding). Buckles can perform four parallel folds, the folding ways are parallel and reel. Three cross folds are each completed by knife which is controlled by servo motor on the second, third and four folding unit.

- The imported straight-grain steel folding rollers guarantee the best feeding force and reduce the indentation of paper.

- Electrical system is controlled by microcomputer , Modbus protocol realizes machine communicate with computer; Man-machine interface facilitates parameter input.

- Smoothly controlled by VVVF with overload protecting function. High precise pile height detector. Sensitive automatic control device of double sheet and jammed sheet. Malfunction display function facilitates troubleshooting; Scoring, perforating, and slitting at request;

- The forth folding can be switched on and off by the main button independently. While carrying out the third folding, the power part of forth folding can be stopped to reduce parts wear and cut the energy consumption down.

- Electrically controlled knife with servomechanism for each folding realizes high speed, superior reliability, and minor paper wastage.

ZYHD780C主要技术参数Technical data:

|

尺寸 |

Model |

ZYHD780C |

|

可折最大纸张尺寸 |

Max. sheet size |

780×1160mm |

|

可折最小纸张尺寸 |

Min. sheet size |

150×200mm |

|

最高折页速度 |

Max. folding speed |

220m/min |

|

平行折最小折页宽度 |

Min. sheet width of parallel folding |

55mm |

|

折刀最高频率 |

Max. folding knife cycle rate |

350stroke/min |

|

可折纸张定量范围 |

Sheet range |

40-200g/m2 |

|

装机容量 |

Machine power |

8.74kw |

|

Overall dimensions(L×W×H) |

5200×1620×1630mm

|

|

|

机器重量 |

Machine net weight |

2400kg |

- 主要性能与特点

该机为组合式折页机,可进行多次平行折页及垂直折页,最多可进行14次平行折或一次平行二次垂直折页。

1、主机为6栅栏+4栅栏+4栅栏机型。

2、可根据需要接ZYD470折页单机完成正反32开折页。

3、配有高精度纸位跟踪探测系统。

4、折辊采用原装进口,抓纸力强、抗锈蚀、粘油墨程度轻。

5、拥有灵敏的双张、堵塞自动控制装置。

6、每组折页单元采用变频无级调速并带过载保护功能。

7、可按需进行打孔、压痕。

8、第一折组栅栏支承板采用钢件组合式结构便于栅栏抬放。

9、斜置输纸辊采用高速龙带传动,噪音小、传动平稳。

10、每折出纸口采用可调输纸过桥。

11、整个电气控制系统采用微电脑控制,各个CPU间能互相通信,采用Modbus协议广播方式,支持与计算机互联通信,各种控制参数通过人机界面设定,数据处理快、运算能力强、稳定、可靠、操作方便、寿命长。

- ZYS780-6/4/4 ,a combined folding machine, can carry out up to 14 parallel folds or one parallel two vertical folds. Host machine is six buckles + four buckles + four buckles model,

- Optional inward/outward of 32-mo with ZYD470 simplex folding machine.

- High precise pile height detector

- Imported folding roller guarantees strong suction capacity, perfect antirust capacity, and low printing ink viscidity.

- Sensitive automatic control device of double sheet and jammed sheet.

- Smoothly controlled by VVVF with overload protecting function.

- Scoring, perforating, and slitting at request;

- Support plate on the first folding unit use steel assembled structure to facilitate the buckles’ lifting.

- Declining paper conveying roller with high speed belt, ensures low noise and smooth transmission.

- Each paper-out port with regulative paper conveying lever.

- Electrical system controlled by microcomputer realizes fast data processing, reliable and convenient operation and longer life. CPU communicates each other; Modbus protocol realizes machine communicate with computer; Man-machine interface facilitates parameter input.

主要技术参数 Technical data

|

可折最大纸张尺寸 |

Max. sheet size |

780×1160mm |

|

可折最小纸张尺寸 |

Min. sheet size |

150×200mm

|

|

可折纸张范围 |

Sheet range |

40-180g/m2

|

|

折辊最高线速度 |

Max. folding roller speed |

160m/min |

|

整机功率 |

Machine power |

7.34Kw

|

|

机器外形尺寸 (S型安装) |

Overall dimensions (L×W×H) |

6500×3200×1630mm |

|

机器重量 |

Machine net weight |

2900kg |